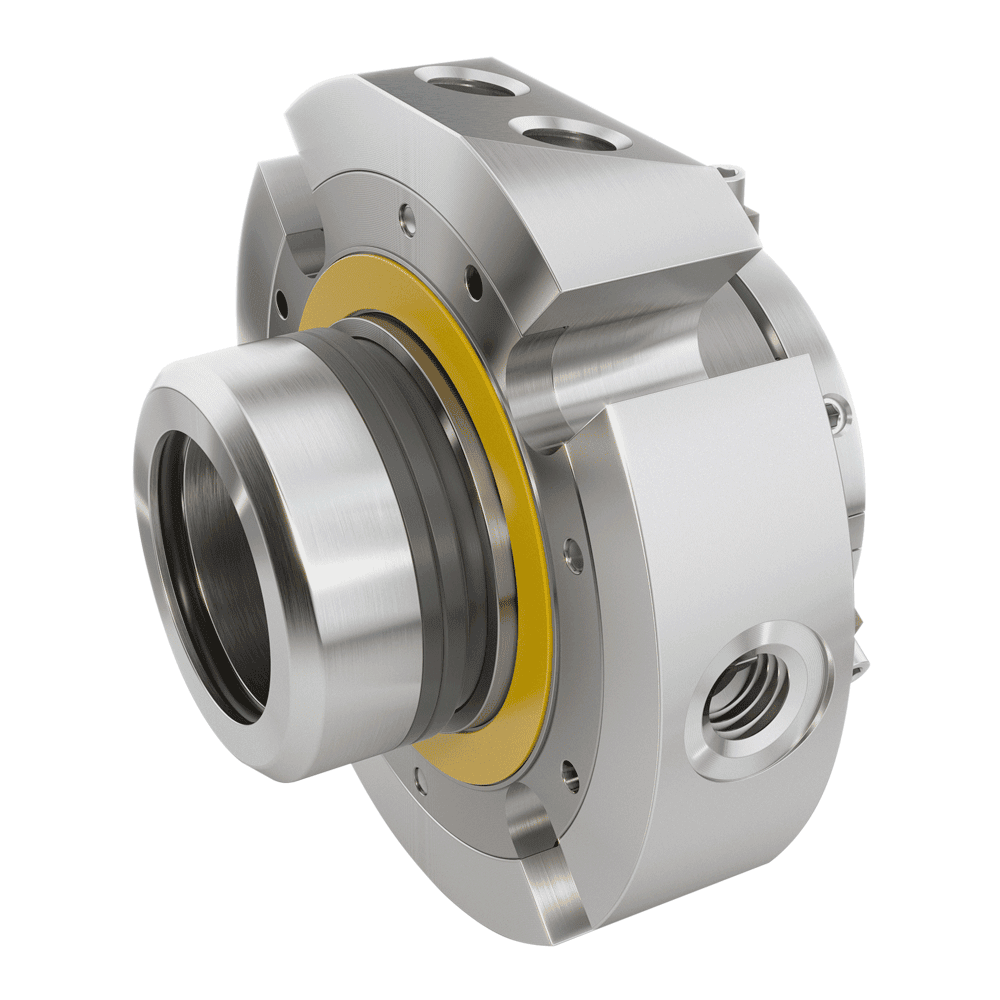

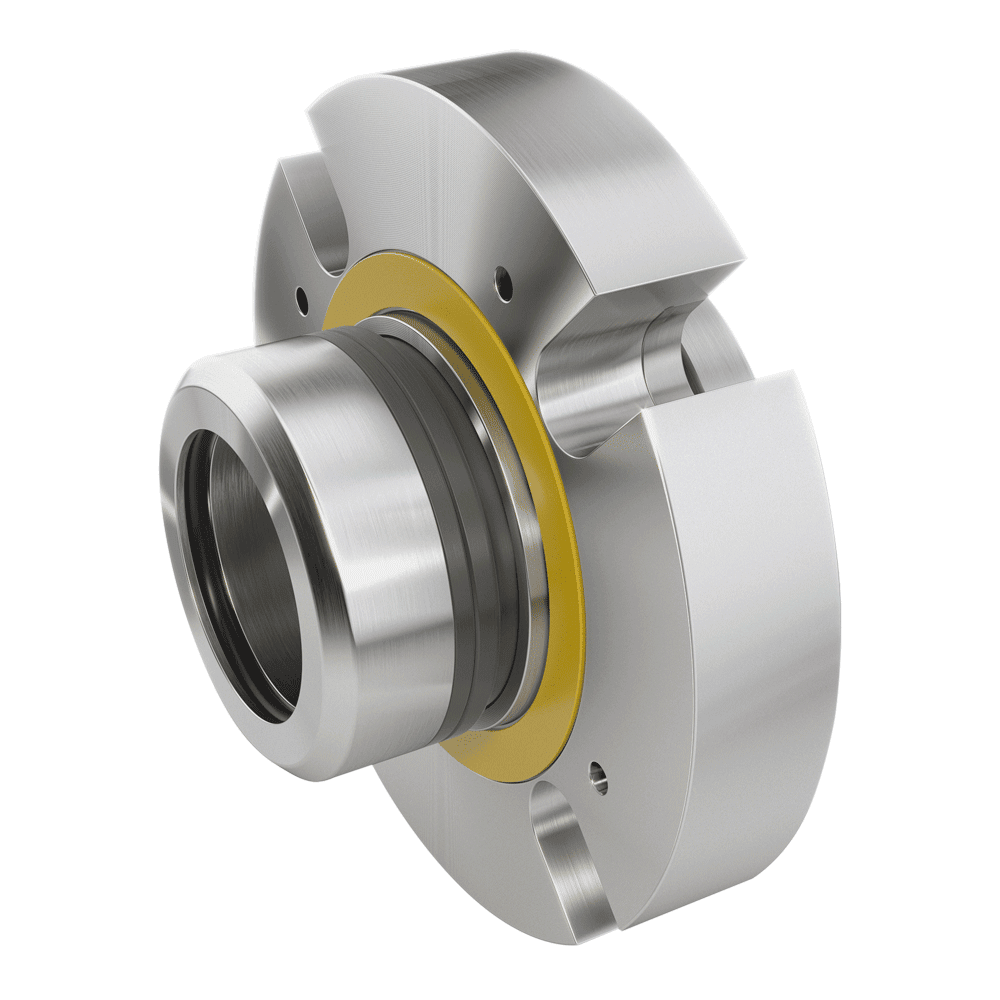

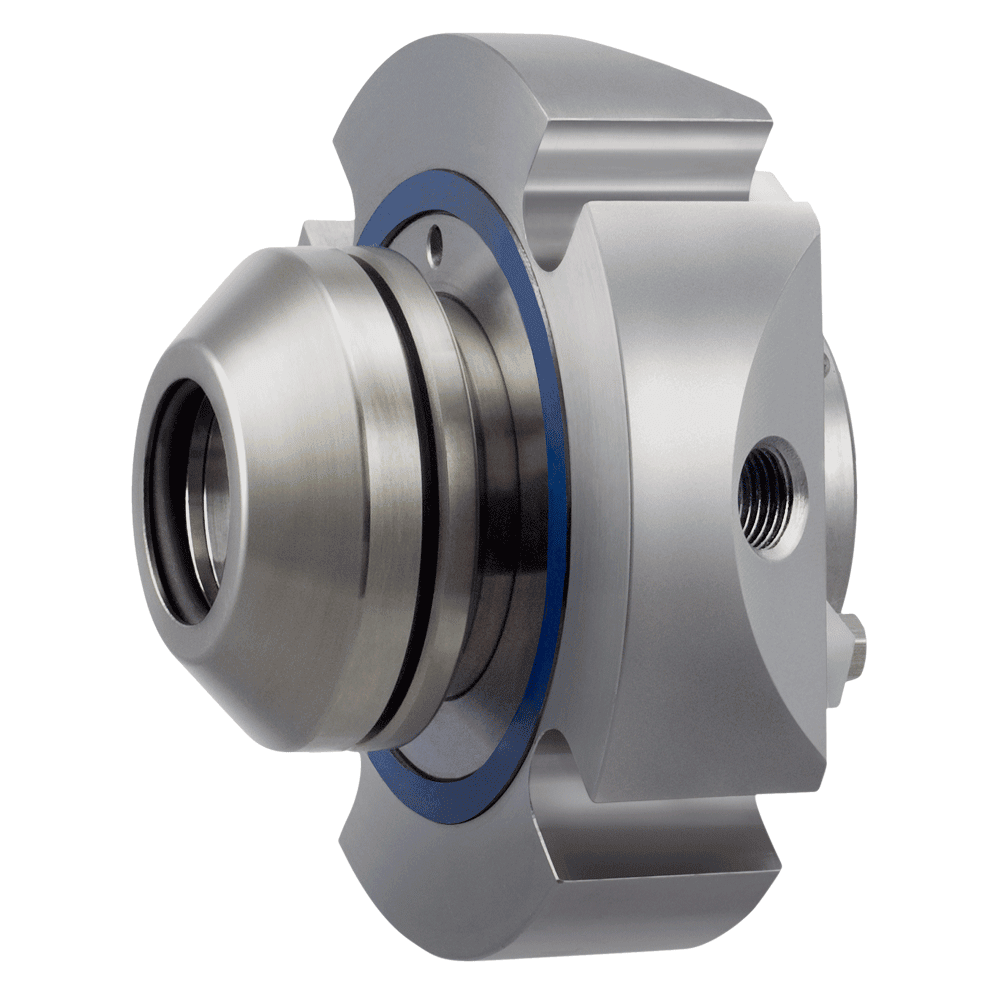

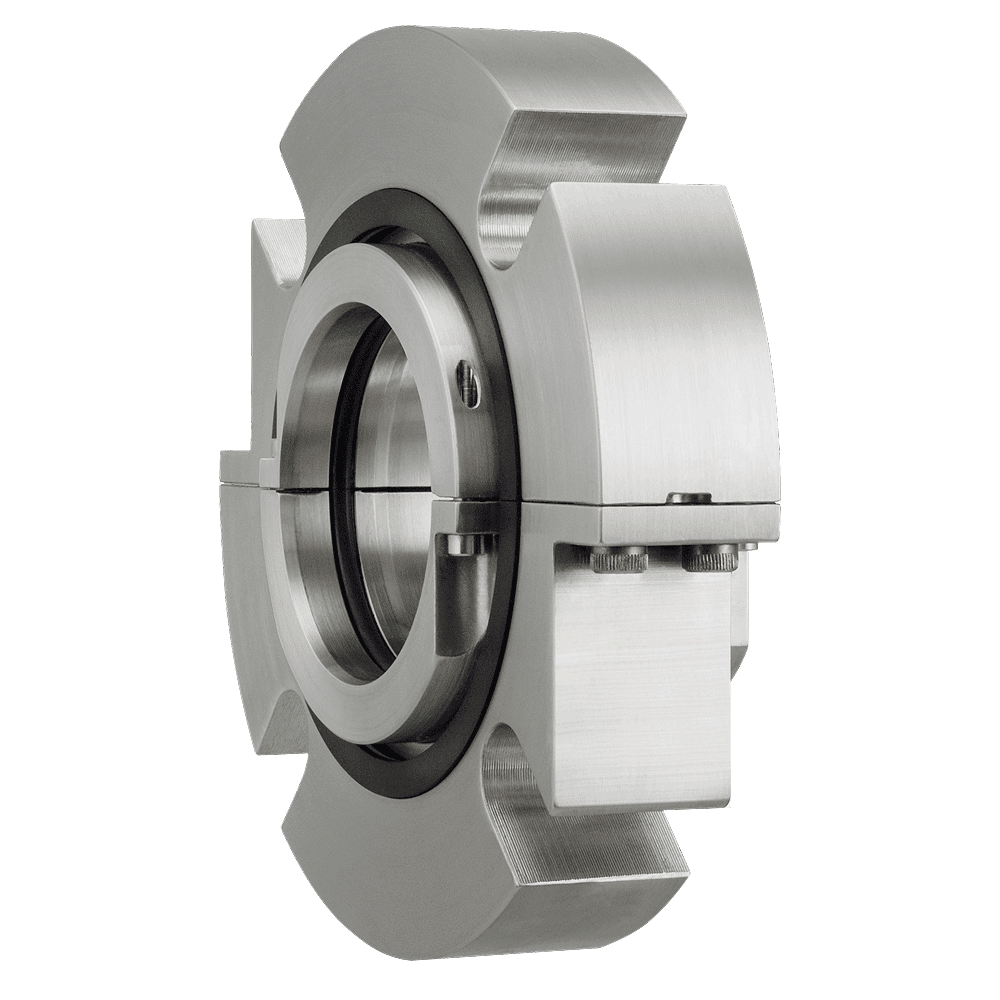

In the complex Chemical sector, it is necessary to foresee particular precautions in the design of mechanical seals for pumps and processing machinery.

The majority of mechanical seals for the chemical industry are planned to operate with aggressive fluids, dangerous and pollutant liquids, but also in the operation of extreme temperature conditions that these liquids can reach during processing. For this reason, the reliability of the sealing systems must be at the top level, in order to allow the productive procedures to operate in complete safety and functionality.

Chemically inert materials are often used for mechanical seals and, depending on the specific sector's use, Alumina, PTFE, Kalrez or FEP O-Rings can be used.

Huhnseal answers all the production standards that underlie the production of mechanical seals for the chemical sector in complete conformity with the regulations in force.

MATERIALS OF MECHANICAL SEALS IN THE CHEMICAL

• Carbon

• Silicon Carbide

• Silicon Carbide with Diamond Coating

• Tungsten Carbide

• EPDM

• Fluorelastomers

• Perfluorelastomers

• PTFE Encapsulated elastomers

• Stainless Steel

• Duplex Steel

• Titanium

• Hastelloy

• Coatings on metal parts

CHARACTERISTICS OF THE MECHANICAL SEALS IN THE CHEMICAL

• Resistance to abrasion and chemical aggression

• Resistance to extreme temperatures

• Long life

• Great reliability

• Easy to be repaired

• Double seals with barrier sealing water

APPLICATIONS OF MECHANICAL SEALS IN THE CHEMICAL

• Vertical and horizontal agitators

• Mixers

• Centrifugal pumps

• Volumetric pumps

• Centrifugal separators