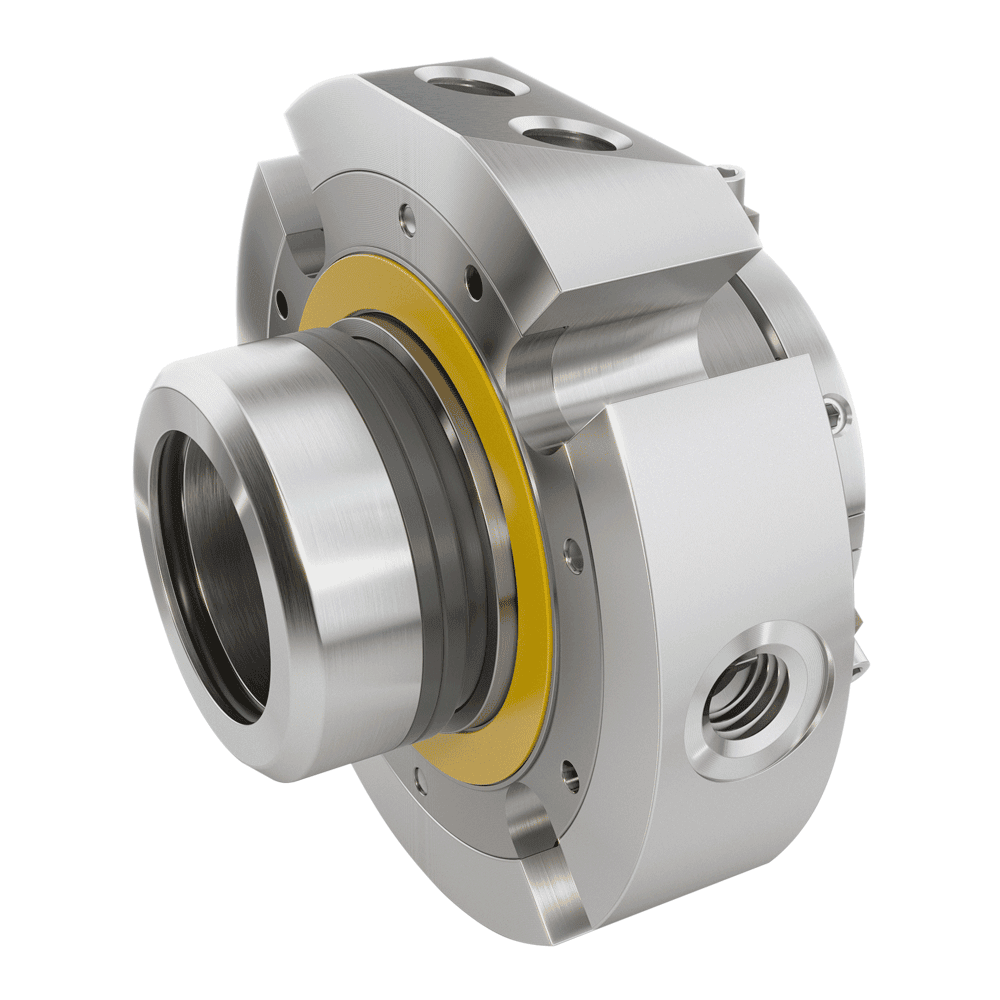

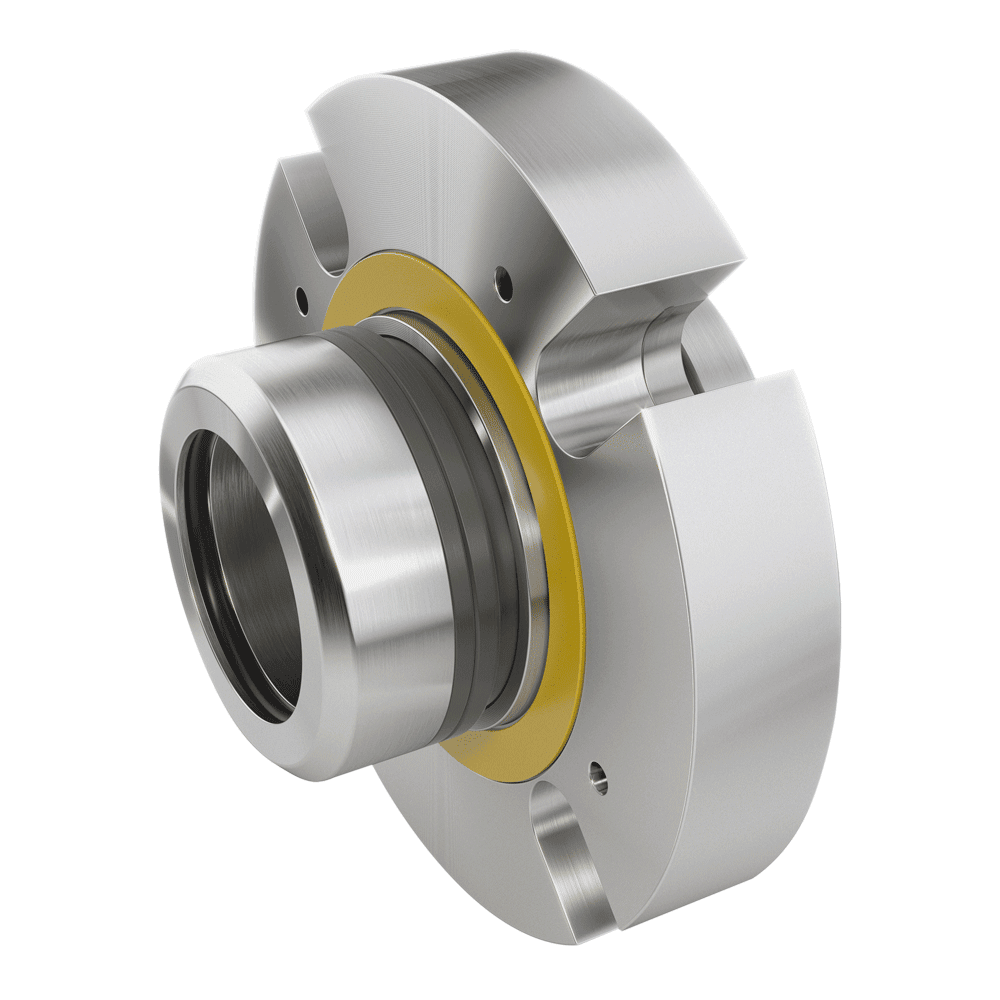

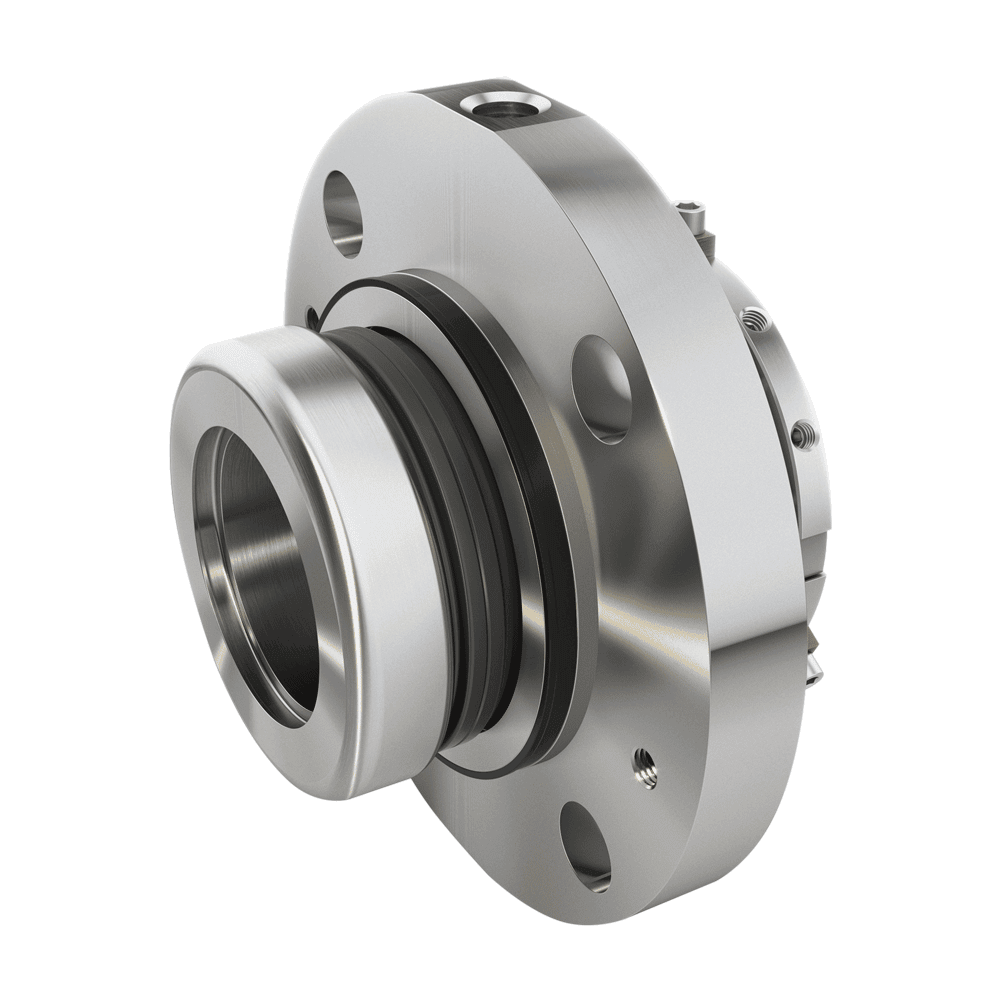

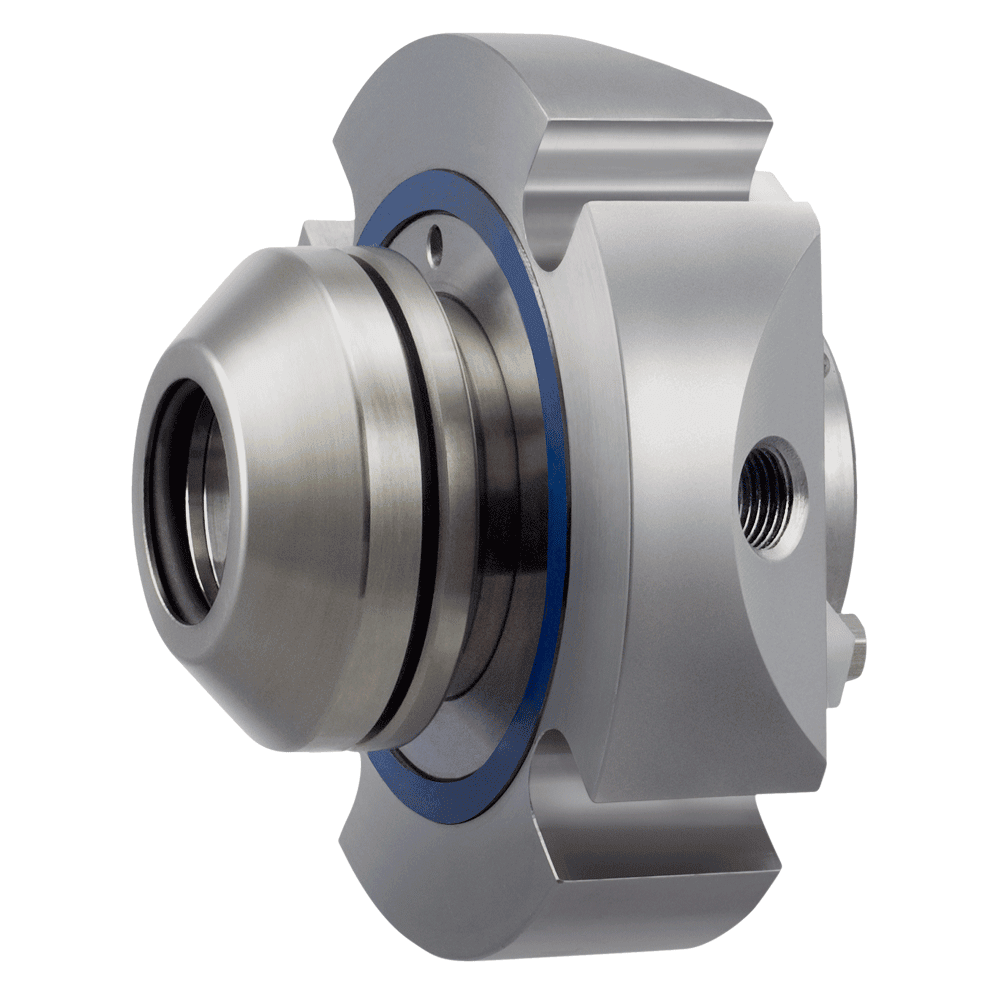

Huhnseal has vast experience designing and manufacturing customised mechanical seals for hygienic purposes.

It is imperative to us that our hygienic sealing products are of the highest possible quality and in line with the latest standards and norms. Huhnseal AB is also an active member of working groups within the EHEDG and 3-A® associations.

Huhnseal is highly devoted to the process of designing the very best hygienic mechanical seals and improving the standards and norms for the hygienic design of mechanical seals and the adjacent equipment, by delivering cleanable-in-place solutions (CIP), that allows end users to sterilize and clean the equipment, without removing the mechanical seal.

Materials used for the mechanical seals for the Food & Beverage applications are strictly Food-Grade.

MATERIALS OF MECHANICAL SEALS IN THE FOOD & BEVERAGE

• FDA, 3-A, USP Class VI, EG 1935 grades

• Carbon

• Silicon Carbide

• Silicon Carbide with Diamond Coating

• Tungsten Carbide

• EPDM

• HNBR

• Fluorelastomers

• Perfluorelastomers

• Stainless Steel

• Duplex Steel

CHARACTERISTICS OF MECHANICAL SEALS IN THE FOOD & BEVERAGE

• Long life

• Great reliability

• Hygienic design

• Easy to be repaired

• Double seals with buffer sealing water

APPLICATIONS FOR MECHANICAL SEALS IN THE FOOD & BEVERAGE MARKET

• Centrifugal pumps

• Positive Displacement Pumps

• Lobe pumps

• Twin screw pumps

• Progressive Cavity Pumps

• Chocolate pumps

• Mixers – all orientations

• Top, side or bottom entry agitators

• Thru shaft prepared food tanks

• High shear mixers

• Homogenizers

• Scraped heat exchangers

• Evaporators

• Colloid Mills

• Butter churns

• Centrifugal separators